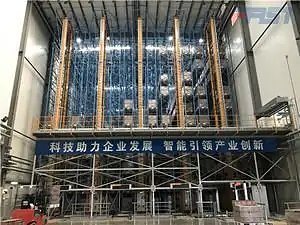

AS/RS Racking

Free Standing Racking

The most oftenly used type of racking in Automated Storage and Retrieval System are: Assembly Beam Type and Bracket Type.

The goods carrier in racking system normally are pallets (steel, wooden or plastic) and cartons/totes. To meet goods storage and retrieval in very high-density, narrow aisle space, the racking system must be manufactured and installed in deadly accurate standard.

Our upright and beam production line all is imported Germany , which able to continuously punching, roll-forming in high precision. For all the project we undertake consulting and designing, we actively carry out Finite Element Analysis and Structure in Extreme Environment Simulation ensure the racking system’s static load stability but also dynamic loading. With almost 30 years history for home and abroad racking project, all of our installation workers are internationalized and experienced.

In all, no matter from theoretical support, manufacturing, installa

Miniload

Huaruide’s storage and retrieval system for boxes (MiniLoad AS/RS) adopt high dynamic value, high efficiency and energy saving driving technology, provides flexible and fast storage and retrieval for trays, turnover boxes, cases, cartons and bins.

Variations:

Bellowing 3 basic lines of stacker crane, each with different speeds and equipment on the services required.

Fork Extractor

With plate extend under load. Available in both single-deep and double-deep configurations.

Side-hook extractor

Extendable side clamps with roller conveyor. Perfect for dynamic storage of varying load sizes.

Dual stacker cranes

Two stacker cranes operate in the same aisle by dispatching system, apply for high-efficiency, multi-stations logistics systems.

Add-ons:

Frontal header

U-shaped circuit located at the end of racking. Ideal for high-frequency storage/retrieval and picking operations. Goods are replenished in this picking position

Pallet Four Way Shuttle

Description:

Comparing with in traditional radio shuttle system, single direction shuttle need to interface with forklift frequently, pallet four way shuttle relies on its own structure, achieves double coordinate movement. It provide a efficient, directly access solution from X and Y axis for entire layer goods’ storage and retrieval.

Through more intelligent collaboration between four way shuttle and stacker crane, the full pallets automated handling, storage and retrieval, inventorying, movement are fulfilled. Pallet four way shuttle is widely used in chain stores, e-commerce, medical, tobacco, express since it has better performance in increasing warehousing demand on storage density, space utilization, and intelligence.

Technical Features:

1. It has safety and obstacle avoidance design, it will stop and alarming when there’s foreign material or goods fell down from pallet.

2. It is high degree of automation, supporting hand-

Shuttle

Features:

It has Vector controlled drive system and accurate positioning, meet for high-frequently input and output requirements;

It has perfect safety refinements and fault diagnosis function;

It transmits information and monitors the entire process;

It can operate with touch screen conveniently, easy for maintenance;

Parameters:

Performance

Full loaded speed

35-45m/min

Empty loaded speed

55-60m/min

Effective working time

8h

Battery

Travelling motor power

400w

Lifting motor power

370w

Voltage

24v

Battery capacity

50-60AH

Weight

13KG

Charging time for 80% electricity at ambient temperature

5h

Charging time for fully charged at ambient temperature

8h

Battery life

At least 1000times recharge cycles

Battery QTY

1

Remote Control

Display

LCD 16×2

Protection

IP65

Power supply mode

Battery

Hibernation

Automatically entering into Hibernation mode after 3 mins

Battery service time under normal using condition

Continuous service time:10hours

Standby time: 1300hours

Parameters

Working temperature

ST: from +5℃ to +45℃

BZ: from -30℃ to +45℃

Unit Load Stacker Crane

Huaruide as a logistics equipment manufacturer and system integrator, is pioneer in China for self-engineering and developing storage and retrieval system products. Flexible to design, manufacture, install height up to 40meters, operate in 1.5m wide aisle width with high load capacity.

With the continuous improvement and refinement, today we have wide range of cranes:

Variations:

Single Deep

Standard configuration of ASRS. One stacker crane with access to racks rows. (One on each side)

Loading: 0.5-1.5T

Height: 7- 24m

Speed: 160m/min

Heavy Duty/Extra High

Loading: 2-6T

Height: 24- 35m

Speed: 120m/min

Multi-aisle Change

Transfer in 2-3 aisles, process 4-6 rows

Double Deep

Extended fork with access to four rack rows (two on each side). Great for high-density storage of low-med throughput.

Dual Carriage

Equipped with 2 independent forks, one stacker crane with access to two pallet positions each time

Light duty SR machine

Loading: 20-50kg

Height: 3-6m

Speed: 200m/min

Variations:

Add-ons:

Shuttle Cart

Shuttle cart powered by sliding trolley transport the pallets to the most convenient position for stacker crane loading and unloading.

Sorting Transfer Vehicle (STV) / Ferry Car

Rail-guided vehicle system connects ground conveyors to AS/RS in/out conveyors.

End-of-aisle Conveyors

Conveyors automatically transport pallets to and from load/unload stations.End-of-aisle conveyors can also transport pallets to/from STVs.

Rack-side Gravity Conveyors

Gravity buffer conveyors installed on ASRS racking side to allow case picking and forklift access.

Remote Monitoring

The camera on stacker crane allows a maintenance worker to check load status in remote, ensure recovery operations faster and safer.

Maintenance cabin

Maintenance cabin on the stacker crane for maintenance and recovery work especially in high-rise warehouse.

Multi-shuttle

Description:

Multishuttle is highly effective for storage, buffering and retrieve totes, cartons, trays or individual bundles. The innovative finger design of the load extractor and telescope arms allow products to be stored single deep, double deep even multi-deep. It is an efficient staging solution that provides precise load sequencing and more operational flexibility at high rates, limited space.

Goods to Person which composed of Multishuttle system, picking station and conveyors is ideal for mixed case pallet building and piece piece pick order fulfillment modules. As a piece picking technology, the goods will be transported to person for picking. GTP system can greatly improve the picking efficiency by transporting goods to person which will cut half of time occupied by walking for person to goods picking. Theoretical picking efficiency of multi-shuttles AS/RS GTP system is 300-1200 orders/person/hour. 5-10times higher than Radio Frequency Picking. Compare to the picking system composed of MiniLoad or rotation containers, multi-shuttles AS/RS GTP system is optimal choice for picking in warehousing industry since its lower energy consumption and higher efficiency.

In addition, It also undertake short-term buffer storage function and serve as a pick face replenishment solution.

Technical Features:

1. Flexible & Extensible system. The system utilize high reliable modular structure, it can be scaled and rapidly replaceable parts as needed.

2. High Efficiency & Flexibility. It adopts full servo system and high redundancy lift architecture, separately running on each level.

3. The innovative design allow flexible single, double or multi-deep storage locations management. Products could be totes, cartons or trays. Dimension range from L300-650mm×W200-450mm×H150-450mm.

Technical Data

Load Types: Plastic tote box, cardboard caton, trays

Package Sizes: Length min.: 200mm Length max: 875mm

Width min.:150mm Width max.:650mm

Height min.: 50mm Height max.: 600mm

Load Weight Capacity: up to 30kg

Load extractor: Telescopic Fixed width arm, Telescopic adjustable width arm and belt conveyor load deck

Storage: Single deep, double deep and multi-deep

Max Speed: 4m/s

Max acceleration: 2 m/s²

Power supply: lithium battery, super capacitor

Operation temperatures:

Ambient: 2℃ to 40℃

Freezer: up to -18℃

Rel. Air humidity: 5% to 90%, no condensation

Reciprocating Hoist

The hoist drive the chain to make the platform reciprocating motion, control the electric motor through variable frequency speed regulating system. There is drive mechanism to let the pallet go into platform automatically. According to input and output direction, there are Z type, C type and E type. The chain speed could be 60m/min with maximum 4000kg load. Due to it can transfer materials up and down hence achieve the materials flowing in the same to two direction in a cycle, greatly improve the throughput while saving vertical transporting space.

Features:

1. Lifting Mode: friction belt type, chain type and toothed belt

2. Pallet Dimension: Available for customization

3. Lifting pallet weight: 100-4000kg (heady duty)

4. Lifting Speed: 1-60m/min

5. Occupied less space

6. Intermittent operating

7. Can be multi-layers docking

8. Belt type with less noise, pollution-free and environment friendly.

Chain Conveyor

Performance Parameters:

Chain Conveyor Length Optimal plan when loading <1500kg

optimum length: 1800mm, 2500mm, 3000mm, 3500mm, 4000mm, 4500mm

The chain conveyor length for hoist is 1480mm

When apply for mobile chain conveyor, optimum length is 1800mm

Chain conveyor width: W=1120. C/C width 1050mm

Chain conveyor height: standard height 600mm, other dimension can be customized.

Standard speed: 11m/min or 14m/min

Structure features:

1. Adopt straight double-stand chain for supporting and delivering goods.

2. Through the adjustable bolts device on each chain to realize chain’s tension.

3. On the vertical beam there’s high strength industrial nylon/steel guide stripes for guiding and supporting, easily to disassemble or replacement.

4. Double-stand straight roller chain makes sure the pallet transportation stable.

Optional Accessories:

Brackets for the photoelectric sensors (fixed, rotary), terminal boxes, end stoppers, dedicated cap for brackets, independent lead-in, guide plate for chain conveyors

RGV

Rail guided vehicle is electrically powered with floor rail, it can transport pallet from chain conveyors to convenient locations for loading and unloading. According to different function, it can be divided into assembly type RGC and transport type RGV. According to different movement mode, it can be divided into Circular Orbit and Linear Reciprocating type (also called ferry cart).

The circular orbit RGV has high efficiency, allow several vehicles working in the same time. Normally adopt aluminum alloy rail. It can be peripherals for AS/RS, but also can be an independent system by itself. As peripherals for AS/RS, it can dock with other logistics system conveniently and automatically to deliver the goods on plan, such as input, output station, buffer station, conveyors, hoist or robot. In addition, it doesn’t need operator, move fast, decrease the storage cost and improve efficiency greatly.

The linear reciprocating RGV (Ferry Cart) includes one vehicle only doing linear reciprocating movements. Lower efficiency than circular orbit RGV.

Roller Conveyor

Roller Conveyor

Mainly consists of driving device (or electrical roller), conveying roller, driving chain (belt), frame structure etc. Through electric motor (or electrical roller) drive the roller to accomplish the conveying. The system is not only convenient, but also very stable and cable for large transport.

Features:

All the components adopt modular structure design, easy for assembly, configuration and high degree of interchangeability.

The frame structure adopts aluminum alloy or powder coated bending material, artistic and easily maintenance.

The roller transmission cable for single chain, double chain, O belt, Wedge-shaped, etc.

Goods on-line storage can be fulfilled by accumulation roller conveying .

Goods movement in horizontal direction can be changed by turning conveying device.

Performance Parameters:

Conveyor Speed: 0-60m/min

Transmission power: chains, multi-wedge, O belt

Roller Diameter: 38/50 (design as request)

Roller Material: steel, steel covered by lagging

Roller Distance: designed by box outside dimension

Frame Structure Material: aluminum alloy, steel

Rack: aluminum alloy, powder coated

Loading Capacity: 60kg/pc (design as request)

Control Mode: PLC on-line automated system

Add-ons:Jacking Type Load Transfer

Push Block Type Load Transfer

Roller Conveyor

Roller ConveyorPallet Roller Conveyor transports goods through chains or belt drives the rollers. It mainly consists of rollers, driving device (or electrical roller), conveying roller, driving chain (belt), frame structure etc. It applied for heavy duty load, high speed, starting and breaking frequently situations.

There is large diameter galvanized steel roller. Each rollersupport by a pair of closed-lubricated ball bearing. Each roller conveyor drives by a electric reducer. We install reducer on a prefabricated bottom rack, formed with frame structure into a whole. Totally they are fixed at the bottom of gyration chains.

Features:

1. All the components adopt modular structure design, easy for assembly, configuration and high degree of interchangeability.

2. The frame structure adopts aluminum alloy or powder coated bending material, artistic and easily maintenance.

3. The roller transmission cable for single chain, double chain, O belt, Wedge-shaped, etc.

4. Goods on-line storage can be fulfilled by accumulation roller conveying .

5. Goods movement in horizontal direction can be changed by turning conveying device.

Performance Parameters:

Conveyor Speed: 0-60m/min

Transmission power: chains, multi-wedge, O belt

Roller Diameter: 38/50 (design as request)

Roller Material: steel, steel covered by lagging

Roller Distance: designed by box outside dimension

Frame Structure Material: aluminum alloy, steel

Rack: aluminum alloy, powder coated

Loading Capacity: 60kg/pc (design as request)

Control Mode: PLC on-line automated system

Structural Mezzanine

Steel platform is mainly consists of post, main beam, sub beam, floors, staircase and frame protector. It can be no on-stie welding. Different design can be provided in line with the loading capacity by selecting different material specification. It is of high intense and widely utilized.

Our storage solutions for steel mezzanines and equipment platforms include:

1.C-Section – Spans up to 20 feet. These spans are usually formed from flat structural steel and are typically used in small to medium-size applications.

2.Beam and C-Section — A beam and C-section combination allows spans more than 20 feet in one direction, while keeping the depth of structure to a minimum. This combination can be used in all size mezzanine applications.

3.Beam and Beam – In this approach, all wide-flange beam design is used when heavy loading or unusual span are required.

4.Beam and Bar Joist — This system is used for medium to large projects were wide spans and high capacity are needed

5.Bar Joist and Girder Joist – This set-up is open-web in both directions and is typically used in large projects or in large spans where high capacity is needed.

Parameters:

Material: Cold-roll Steel Q235

Racking Finish: Powder Coated Finish or Galvanized

Height: 3000-4000-4877-5000-6000-7000-8000-9000 mm

Length: 800-900-1000-1200-1300-1400-1500-1600-1700-1800 mm

Load Capacity: 100-1900 kgs per sqm

Different sizes, various specifications and colors are available according to customers' different needs.

World class Manufacturing: Only quality certified steel: ISO 9001-2000 Quality Assured,CE certificate

World class Design standard: Design to AS4084-2012 and International Standards ISO9001,

Complies With European FEM Regulations and All codes including SEMA.

Mobile Racking

Electric Mobile Racking, is one of the high-density racking system. It only requires one chanel, with very high space utilization. Through the electric motor driving and frequency control, make the racking from start to running all in stable situation, the security get guaranteed. According to the structure types, there are rail type and without rail type.

Push Back Rack

Push rack also called pushback rack, its lanes equipped with consists of beam racks, rail and wheel pallet cart. Huaruide design the cart frameworks on the rail. When the goods are picked up, the Last in pallet is First out frictionless movement. When the frontal cargo pallet is discharged, the goods will automatically move down to the aisle by gravity, so that advanced backward storage can be realized and there is always a pallet at the front of the rack for picking.

Comparing with driving rack, and double deep beam rack, it has more advantages on retriev goods. The maximum deep can be 5 pallets deep. It also has less requireemnts for the forklift than drive in drive thru racks, only need to work at front of aisle.

Advantages of Pushback rack:

It controls inventory by pallet, ensuring Last-In-First-Out

Pushback racking stores multiple SKUs on various levels of lanes for easy product access.

It maximizes warehouse capacity and space utilization, the operator only need to work at the frontal aisle.

Available in 2 to 5 pallet deep styles — depending on product volume and warehouse configuration.

It can be arranged as standalone bay, or integrate as a back-to-back system.

Gravity Pallet Flow Rack

Carton flow racks is the ideal solution for products which have strict requirement on FIFO (First in First Out Solution).

The wheel we adopt is high quality thermoplastic material, with minimal friction coefficient and small impact resistance. On its chemical performance, it has acid and weather resistance, without water absortation. The U shape channel is made of galvanized steel plate with round corner treatment. The roller made of stainless steel with 6kg/roller loading capacity. Our Huaruide flow rack all use import Germany Euroroll fluency strips, work in stable, heavy load with very low noise. Meantime they can adjust the flow width according to aisle, working well in below 40degree.

Not only as an alternative to drive in/thru static racks for conventional warehouse. In some cases we provide, flow rack also integrated with warehouse unitload automated storage & retrieval system (AS/ RS). Comparing with Stacker Crane combines single deep or double deep AS/RS storage langes with multiple depp, high-density configurations in the same aisle, a custom designed gravity flow rack system also can benefit your operation. This pallet flow system allows pallets to the convey automatically and accumulate at the discharge end. There is no power or air source. Therefore, this storage system offers benefits of reduced labor and handling cost, cut off the additional operating expenses.

Advantages of Gravity Flow Pallet Rack System:

Working well in cooler and freezer (up to -40℃) warehouse

Import key components from Germany with durable service life and quite operating environment

Triple rail supports to protect the pallets

Direct access to the pallets

Stand alone or easily integrated with other material handling system

High flexibility and extension for future configuration

Drive in / thru Rack

Advantages of Drive In/Drive-Thru Pallet Rack:

a) LIFO/FIFO (last in, first out/first in, first out) configurations

b) Reduces space, cuts cost, and holds more loads with its deep lane storage

c) High volume, low SKU

d) Eliminates the need for multiple aisles

e) Provides control over entry and exit

f) Favors density as opposed to the selectivity of Selective Pallet Rack

g) Designed specifically to suit your pallets and forklifts

Detailed Description of Drive In/Drive-Thru Pallet Rack:

Material: Cold-roll Steel Q235

Racking Finish: Powder Coated Finish or Galvanized

Upright sections: 80*60*2.0mm, 90*65/70*2.0mm, 100*70*2.0mm, 120*90/95*2.0-3.0mm, etc

Box beam sections: 80*50*1.5mm, 100*50*1.5mm, 110*50*1.5mm, 120*50*1.5-2.0mm, 140*50*1.5-2.0mm, 160*50*1.5-2.0mm,etc.

Load Capacity: 500-6,000 kgs UDL/beam level.

Height: 4000mm-15000mm

Depth: 1.8mm-2.5mm,3-12 pallets

Different sizes, various specifications and colors are available according to customers' requirements.

Structure of Drive In/Drive-Thru Pallet Rack:

AGV

Backpack type AGV also called transport type AGV, It though roller, chains, belt on the vehicle cooperate with all kinds trasnportation equipment, complete material transportation in several positions. It is widely used in tobacco, medecial, beverage, storage, appliance, print, mechanical, chemical, etc. It works stably, high accuracy, fast speed and heavy load.

System Structure:

1.Through all kinds trasnportation equipment, realize automated conveying line docking.

2.Following backpack conveyor adjustment mechanism, to realize multi specification, multi categories conveying.

3.Flexible routine ready for future optimization and extension.

4.Computer management system and wireless LAN communication technology realize scientific production scheduling and management.

5.Adopt infrared, laser, radar..etc security detection syste, achieve around staff security

Performance Parameters:

Control Mode: controller centralized control, monitoring and management

Control Method: Fully automated/ Semi Automated/ By Manual (Optional)

Communication: Wireless LAN

Navigation Mode: Magnetic Navigation

Driving Mode: Servo steering wheel or differential driving

Charding Method: On-line fast charfing / off-line charging

Dirving Speed: 0-80m/min, CVT

Climbing: 3-5°

Loading capacity: 0-5000kg

Safety induction range: ≤3m (adjustable); emergency braking distance ≤20mm

Robot Palletizer

Robot palletizer is an intelligent and high efficient stacking machine. Because of it’s dexterous and light mechanical structure and flexible operating mode, is replacing frame mechanical palletizer, become the more and more factory’s wise choice.

Robot palletizer is mainly designed for package application, its jointed-arm occupied less space, is convenient for integrate into package process. In the meantime, the robot handle the goods transportation through arms, make the material and later palletizer flexible coombined, drastically reduced packaging time and improved production efficiency.

Robot palletizer has high accuracy, it grab the goods very accurately, and quick response. All the palletizing and driving movement through servo and related control system realized. They can do repeat programming through off-line programming, according to different batches realize different palletizing mode’s fast switching. One robot palletizer can fulfill several lines’ working together.

Performance Parameters:

Structure Mode: Abb, Yaskawa, Fanuc, Kuka

Palletizie Good Condition: bags, cartons

Palletizing Mode: as request

Palletizing speed: 600-1200 nos/hour

Maximum Pallet DImension: 1200mm×1000mm

1400mm × 1200mm

Palletize Height: Maxmimum 1800mm

Palletize Wight: Maximum 200kg

Robot Claw: clamp, fork, sucker, etc.

Memorization: standard 30 categories, maximum 400.

Advantages:

1.Robot has strong digital operation function, high accurate operation to realize fast loading, palletizing and depalletizing.

2.In production line, the loading, palletizer and depalletizer robot can be rationally distributed, the ideal solution is one robot responsible for two or more lines working at the ends.

3.The servo motor, programmable controller, frquency transformer all is first-clss brands, the hardware realibility and service life can be guaranteed.

4.High quality hardware works perfectly with Huaruide designed control software, achieved high degree of system automation. We also offer complete interlock mechanism for equipment and operators protection.

5. Huaruide excellent technican, stable and realible products quality, service improve the workshop automation level.

Palletizer / Depalletizer

Product structure:

1.Adopt modular structure, can be easily assemble into a whole system.

2.Complete electric interlock protection. When the palletizer/ depalletizer is in the middle of movement, the lifting mechanism will be locked.

Performance Parameters:

Conveying motor power: 0.55KW

Lifting motor power: 1.1KW

Fork mechanism: 25W (0.12 ×2KW)

Control mode: PLC control / central control

Surface treatment: powder coated for frame structure

Empty pallet stacking: 4-10pcs

Lifting Weight: 500kg

Supporting Height 600-900mm

Lifting speed: 12m/min

Cross Belt Sorter

The cross belt sorting completed by “cart”. When the cart moves to designed position, the belts runs out the cargo. Due to not be affected by goods weight, dimension and friction factor, the goods range, feeding aisle, unloading speed, sorting accuracy and operating stability are greatly improved.

Structure Features:

1.Exquisite layout, can make adjustment according to on-site situation.

2.The accessories is flexible to according to different business mode, it can be rich functional, complicated business, large on-site layout but also can be full featured compact layout.

3.Customizable.

4.Modular system easy for assembly.

5.Universal applicability for irregular heavy goods sorting.

6.Frame structure made of aluminum alloy or powder coated bending steel, it’s perfect and practical.

7.Multi sorting exits, can be sorted from both sides.

8.High ability of sorting, normally it can be 15000-20000pcs/hour

Sliding Shoe Sorter

Structure Features:

1. Safely sorting for products. Adopt special ABS sliding shoe, delivering the goods in the mean time send to the designated exit, so the goods won’t be damaged.

2. High efficiency. When the conveying speed is 150m/min, if the box minimum dimension is 200mm, with 600mm distance, then our maximum efficiency can be 11250 pcs/ hours.

3. Low noise. When is speed is 100m/min, noise level equals to 73db±3

4. Advanced mechanical performance and durability. The sliding shoe work in guide wheel, also they keep distance with guide wheels and conveyor, even though there are adhesive tapes or other foreign matter, the sliding shoe still work. We also insert safety detection device for knowing chains degree of tightness or sliding shoes derailed.

Performance Parameters:

Sorting Efficiency: 8000pcs/hour in average

Max Conveyor Speed: 150m/min

Single conveyor length: max 65m, can be assembled

Conveyor Width: 1000-1500mm

Conveyor Height: 1000-2500mm

Goods condition: boxes, bags, totes, trays, etc.

Goods minimum dimension: L200mm×D20mm×H10mm

Goods maximum dimension: L1200mm×D700mm×H600mm 30kg

Line Shaft Diverter

When the rotating inclined guide wheels go up and down between belts in parallel, the cartons or box will be sorted and go to the right direction. Line shaft dirverter was widely adopted after the second war in American and Japanese logistics center, today it has been mature technology and well applied in developed countries’ logistics centers.

Structure Features:

1. Consists of conveying wheels, synchronized steering controller, driving devices, frame structure, etc.

2. According to the system’s command and information recognition, steering controller to change the wheel movements, send the boxes to diverter conveyor.

3. The wheels are covered with O type polyurethane ring, effectively prevent boxes from damage.

4. Widely adapt for all kinds of logistics centers, cartons, boxes, trays, bottles, books , package and electronics, etc.

Non-power Conveyor

Non-power conveyor is an easy, flexible, and low cost conveying equipment. It is widely adopt in warehouse and logistics center. Mainly includes non-power roller conveyor and skate wheel non-power type.

Structure:

1.Applied for in-house environment.

2.Simple structure, economical.

3.The goods transportation need to be pushed by labor or a certain degree tilt.

4.Applied for box type or flat bottom.

Chain Plate Conveyor

The chain plate conveyor especially applicable for irregular heavy duty goods transportation. We choose big hollow roller with chains, in the both sides the synchronized accessories connected by plate shape elements formed into continuous plate.

Structure Features:

1. All the components adopted by modular structure, easily for assembly.

2. Frame structure made of aluminum alloy or powder coated bending steel, it’s perfect and practical.

3. It can cooperate with climbing conveying unit, turning chain plate conveying unit to realize goods transportation direction changing in X and Y axis.

Vertical Conveyor

Spiral Hoist

Our vertical Conveyor mainly includes spiral hoist and continuous hoist. They realized for cartons, boxes vertical, largely, continuously and stable transportation.

Continuous Hoist

Continuous hoist widely used in food, beverage, pharmacy, chemical, apparels, and logistics distribution. It requires small occupied land, easy for maintenance, working stable and reliable but lower cost.

Belt Conveyor

Mainly consists of driving device (or electrical roller), tension device, conveying belt, supporting roller, supporting plate, frame structure, etc. Through electric motor (or electrical roller) drive the belt to accomplish the conveying. The system is not only convenient, but also very stable and cable for large transport.

Features:

1. All the components adopt modular structure design, easy for assembly, configuration and high degree of interchangeability.

2. The frame structure adopts aluminum alloy or powder coated bending material, artistic and easily maintenance.

3. The belt adopt rubber, silica gel, PVC, PU and other materials; In addition to the delivery of materials for the ordinary, but also to meet the materials with special requirements like: oil, corrosion-resistance, anti-static. The food grade belt apply for food, pharmacy industry.

4. It can adopt climbing belt conveying unit, turning belt conveying unit to realize goods direction change in horizontal and vertical.

5. On the conveyor can add lifting plate, edge accessories and so on, to realize lift in large angle.

Carrier & Shuttle

Description:

In carrier and shuttle system, we’ll put a rail perpendicular to the aisle on each layer, the shuttle goes into the aisle to carry the pallet back to carrier, meantime, it get charged on the carrier. Carrier bring the shuttle with pallet to outbound system like vertical lift or conveyors. Also, the carrier can take the shuttle to different aisles. In carrier&shuttle system, our WMS/WCS control shuttle, carrier, hoist, conveyors to achieve fully automated operation. The system has great performance in improving the high density storage, saving the storage&retrieval time, decreasing labor’s working time and strength.

Performance and Advantages:

Hidden jointing slide-wire power supply and guide rail technology (Invention patent No.: 2013101426242)

Electrical motor from international famous brands

Excellent acceleration performance and operation stability

Global leading automatic lossless charge-discharge technology

Smart no electricity breaking technology

Advanced smooth ON-OFF operation

Powered by leading super capacitor, unrestricted recharge cycles

Online charging without human intervention, smooth operation

Obstacle-free shutting technology (Patent No.: 2018SR321627, 2018SR324252)

Technical Parameters Table

Type of Carrier

Non layer transfer type

Layer transfer type

Carrier Code

HRDSZS

HRDSZM

Carrier Power Supply Mode

Power by slide wire

Power by battery

Power by slide wire

Power by battery

Load Capacity

1500

1500

1500

1500

Applicable Pallet Size (pallet length mm)

1100 1300

1100 1300

1100 1300

1100 1300

Speed

Carrier empty load

2.5

1.5

2.5

1.5

Carrier fully load

2.0

1.0

2.0

1.0

Shuttle empty load

1.0

0.9

1.0

0.9

Shuttle fully load

0.6

0.5

0.6

0.5

Motor power

Carrier drive motor

2.2 (AC380V)

1.5 (DC48V)

2.2 (AC380V)

1.5 (DC48V)

Carrier chain motor

0.4 (AC380V)

0.4 (DC48V)

0.4 (AC380V)

0.4 (DC48V)

Shuttle drive motor

0.4

0.4

0.4

0.4

Shuttle jacking motor

0.37

0.37

0.37

0.37

Carrier battery

Battery capacity Ah

80

80

Continuous working hours on a single charge

8

8

Charging time h

8

8

Shuttle battry

Battery capacity Ah

Super capacitor

50Ah (DC24V)

Super capacitor

50Ah (DC24V)

Carrier & shuttle charging mode

On-line

On-line

On-line

On-line

Control mode

Manual, Automatic,On-line

RVVP INTERNATIONAL CORP.